A new office – quickly and without construction work

Rather than constructing offices that can’t be moved if you relocate your company, Pedlex proposes installing modular in-plant offices, which also offer the advantage of shorter construction times, while avoiding the noise and dust of a typical construction site.

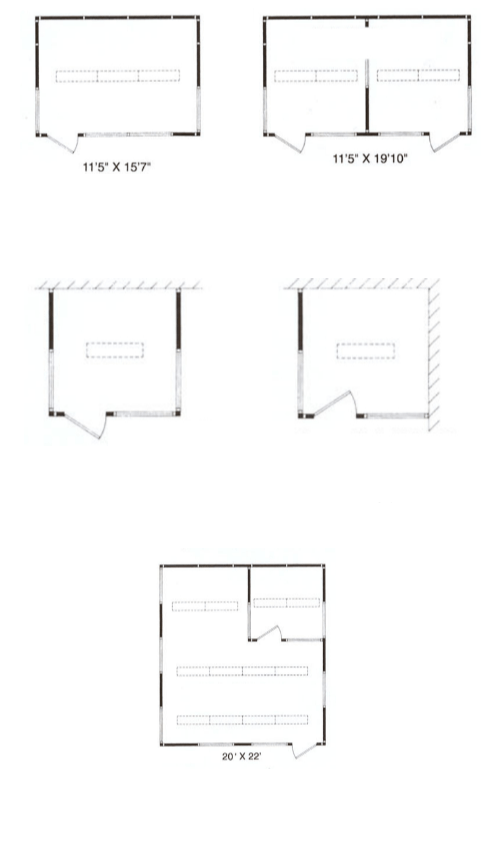

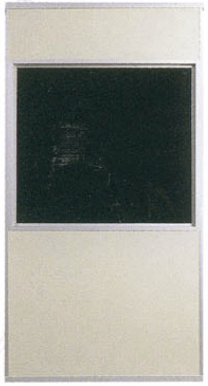

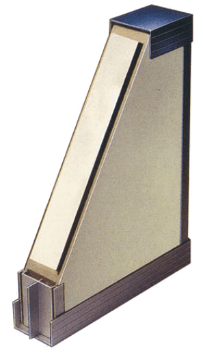

Our ModTech system for portable modular office buildings by Canadian Portable Structures consists of modular walls that can be easily put up and taken down if the office needs to be moved. Ideal for supervisor offices, shipping and receiving, dining areas, guard shacks and laboratories, our modular inplant offices are custom designed by experts according to your needs and your budget.

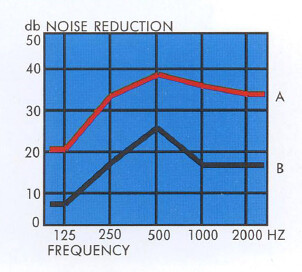

The walls and ceilings of our portable prefabricated buildings isolate noise (30db or 38db reduction with its Sound Stop technology) and can be easily stacked to build a sturdy 2-level structure. Their quick and safe assembly allows you to equip your warehouse, construction site or factory, without disrupting your current operations. Modification and disassembly of our modular offices are easy, allowing you to accommodate your evolving needs.

Take a 360° virtual tour in the modular in-plant office we installed in our warehouse, where our logistics team works every day.